Anything is possible when it comes to machining with our broad selection of general insert milling grades and geometries.

Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to optimize your milling operations for increased productivity.

The Seco comprehensive grade and geometry range covers all material groups and allows you to achieve improved material removal rates, tool life and surface finishes.

For enhanced performance, many of our variants are coated with CVD or PVD layers on the carbide substrate.

Before you dive into the strength and the alignment of our Seco milling grades, understand the nomenclature involved.

Newly launched grades follow a simple nomenclature format that allows you to quickly understand grade characteristics and suitable working ranges.

For historic reasons, many grades do not adopt the new nomenclature. These legacy grades will be updated as new generations launch.

Understanding the diversity of Seco milling grades’ strengths and alignments will help guide you to the best choice for the material you are machining.

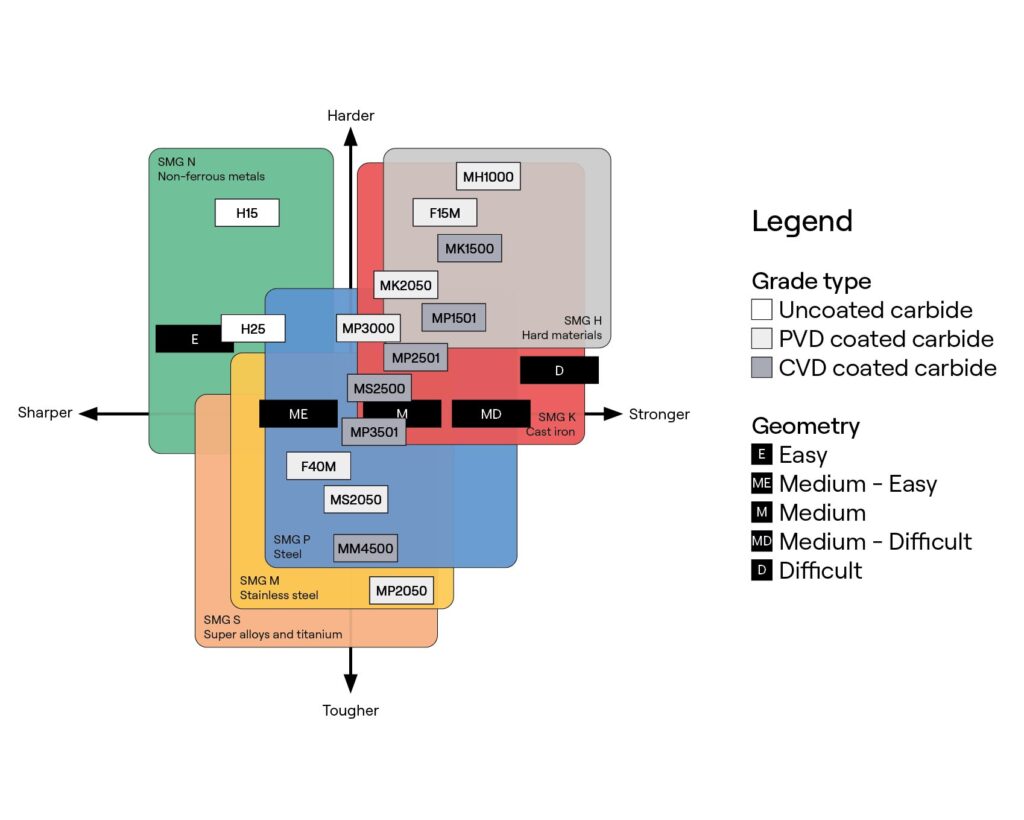

Our General Grade Mapping chart below will help optimize your application with the appropriate combination of grade and geometry.

This chart provides an overview of most milling grades in the context of workpiece material. The chart also shows basic grade toughness, as well as geometric characteristics for sharpness and strength. Based on workpiece material, you can identify suitable grade/geometry combinations as a first orientation. You can also see the various types of materials a grade can machine as well as suitable geometry matches.

From top to bottom, the chart arranges grades by increasing toughness, with the toughest grades indicated at the bottom.

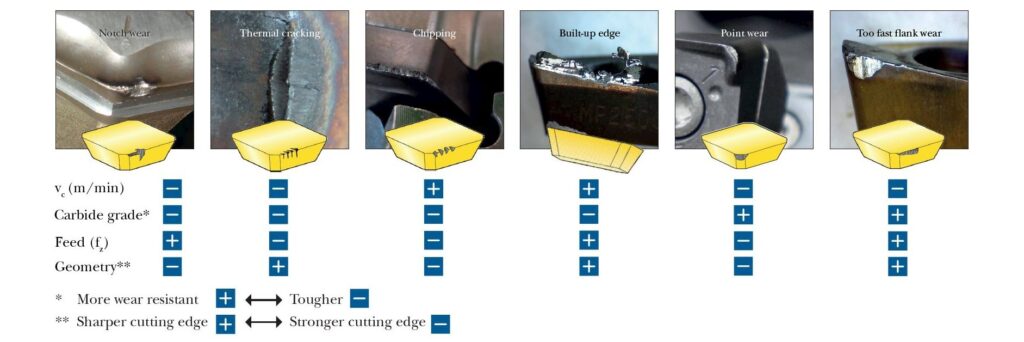

Tougher grades can handle higher chip loads and enable the use of sharper geometries, work with interrupted cuts or vibrations, heterogenous workpiece conditions, and machine in inclusions with less edge chipping and disruption.

Tougher grades also have fewer issues with the thermal cracking and notch wear that can be challenges in milling. The drawback with tough grades is that they tend toward higher flank, crater wear and plastic deformation, which require an adjustment toward the harder, more wear-resistant grades shown at the top of the chart.

In addition to grade, the insert geometry has a tremendous impact on the machining process and the way the grade behaves and wears.

A hard grade combined with a too-sharp geometry can easily chip and fracture during extreme interrupted cuts or when machining in inclusions.

Conversely, extreme thermal and abrasive conditions will adversely impact tool life on an insert with a tough grade and heavily protected geometry.

Optimizing your tool life and application is always a balance between insert grade and geometry.

For each product family, Seco provides a first choice of grade and geometry based on material group. This reduces complexity and provides a starting point for further optimization. The digital catalog and Seco Suggest online application provide this information.

CVD Grade Offering | MK1500 | MP1501 | MP2501 | MS2500 | MP3501 | MM4500 |

Mechanical Shock Fracture Resistance | * | *** | *** | **** | **** | ***** |

Thermal Shock Resistance | * | ** | *** | *** | **** | **** |

Thermal Wear Resistance | ***** | **** | **** | *** | **** | ** |

Abrasive Wear Resistance | **** | **** | **** | *** | *** | ** |

Crater Resistance | ***** | **** | *** | *** | *** | ** |

Material Strength | K | P, K, H | P, M, K | S, M, P | P, M, S | M, S, P |

PVD Grade Offering | MH1000 F15M | MK2050 | MP3000 F30M | MS2050 | F40M | MP2050 |

Mechanical Shock Fracture Resistance | * | *** | *** | **** | **** | ***** |

Thermal Shock Resistance | ** | *** | *** | **** | **** | *** |

Thermal Wear Resistance | *** | *** | *** | *** | ** | **** |

Abrasive Wear Resistance | **** | ***** | *** | *** | ** | **** |

Crater Resistance | *** | *** | *** | *** | ** | *** |

Material Strength | H, K | K, P, H | P, H, M | S, M, P | P, M, S | P, M, S |